SUBSA Implementation Partner

SUBSA (Solidification Using a Baffle in Sealed Ampoules)

SUBSA is a high-temperature furnace on the International Space Station (ISS) that melts materials at a controlled rate, holds at maximum temperature to stabilize, and then solidifies at a precise cooling rate via a gradient freeze technique in a microgravity environment. A transparent zone in SUBSA enables high-definition imagery to observe the solid-liquid interface formation and adjust thermal parameters in real time. Thermocouple sensor channels are available for measuring sample thermal profiles at a user-defined frequency rate, along with optional overlay of science data on a video feed. With a maximum temperature of 850° C, SUBSA’s precision heating and cooling control supports up to 8 process segments, including various combinations of dwell, heat-up, or cool-down periods with resolution and stability of 0.1° C on the setpoints and 0.1° C/hr on the ramp rates. SUBSA command and control is performed from a ground-based, secure Mission Operations Center.

CSS – SUBSA Implementation Partner

CSS was selected by NASA to operate and maintain both the SUBSA hardware on the ISS and its ground analog system and operations facilities. CSS supports NASA and other government agency-awarded investigators through a prime contract and is authorized to work directly with potential commercial and academic users. CSS provides comprehensive support and services to our customers to define and implement use requirements. Our team conducts required safety analyses and verifications, supports experiment pre-flight testing and validation, and coordinates all logistics for delivery and operation on the ISS. CSS is partnered with Redwire Space Technologies to provide development and integration of material crucibles (Science Ampoule Assemblies) and real-time furnace operations and data collection on both the ISS and ground analog facilities.

Advantages of Microgravity for Application Development and In-Space Manufacturing

SUBSA capitalizes on two significant physical aspects of microgravity:

- Reduced buoyancy-driven convection – a more stable and undisturbed solidification environment, promoting a more homogeneous microstructure.

- Reduced sedimentation – a more uniform distribution of constituents, potentially enhancing strength and other properties.

Using SUBSA in microgravity provides many benefits, including:

- Finer and more uniform grain structure – can enhance the mechanical properties of the material.

- Reduced segregation – a more homogeneous material with improved properties.

- Reduced porosity by eliminating gas bubbles – a denser and stronger material.

- Improved modeling – validate and improve computer simulation models used to predict terrestrial solidification behavior.

- Advanced manufacturing techniques – development of new and improved metal processing and manufacturing techniques.

Terrestrial Applications

- Improved metal and alloy manufacturing

- Enhanced semiconductor and metal / metal-alloy crystal growth

- Production of amorphous metals

- Metal additive manufacturing (3D printing)

Markets

Aerospace

Electronics

Medical devices

Pharmaceuticals

Military hardware

Industrial casting

Energy storage

Manufacturing R&D

Contact us

Find out more about SUBSA and CSS’s capabilities.

Service Inquiry

Additional Projects

Coastal Aquaculture Program / Coastal Aquaculture Siting & Sustainability Program

CSS supports the NCCOS mission to provide high quality science, guidance, and technical support to coastal managers to grow sustainable aquaculture while maintaining and improving ecosystem health.

Training for First Responders and Field Staff

CSS technical experts prepare and deliver essential training and information addressing worker safety and environmental hazards.

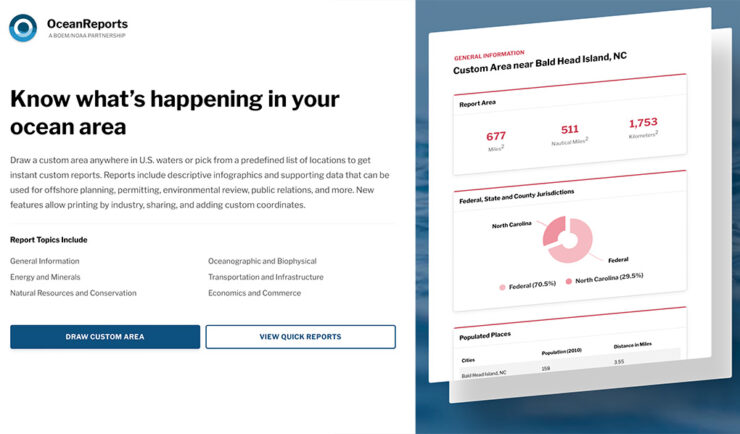

Development support of NOAA/NOA OceanReports

CSS’s Team helped create the OceanReports web-based tool that assists in the analysis of coastal and marine resources for commerce, development, and conservation.

Get in touch

Contact us to learn more about our projects, capabilities, solutions, and service offerings.